Chemical plant leak detection

Natural Gas Safety Monitoring System

System Introduction

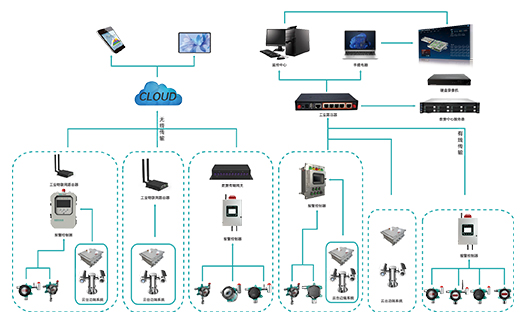

The NGSM System is composed of laser methane detection equipment, control cabinet and system software, among which the laser methane detection equipment is the core equipment of the NGSM System. The product is designed based on TDLAS laser gas detection technology, and the absorption amount of light molecule gas of specific wavelength is analyzed and calculated by harmonic algorithm, so as to realize long-distance and non-contact methane gas detection. The NGSM System can realize real-time monitoring and early warning of natural gas leakage disasters and realize 7×24 hours unattended, which can not only improve the inspection efficiency, reduce the pipeline monitoring cost, but also avoid the safety risks caused by human negligence and error. Once the production unit leaks, on-site personnel can obtain relevant information in the first time. Implement security measures and emergency plans in a timely manner. The following shows the system topology.

System Characteristic

The use of advanced laser gas detection technology, 7×24 hours for large area coverage monitoring.

Set explosion-proof video and gas detection function as one, 360° Rotating line-type optical beam gas detector No dead Angle monitoring No dead Angle monitoring.

Fixed point automatic cruise can be set to achieve unattended.

The platform software can realize customized intelligent AI functions such as perimeter and helmet recognition.

Highly selective to methane gas, not affected by other gases and weather, low false alarm rate.

Support solar power supply, wireless communication function, adapt to various special scenarios.

Application Scenario

LNG filling station, gas station, natural gas pipeline network transportation and storage.

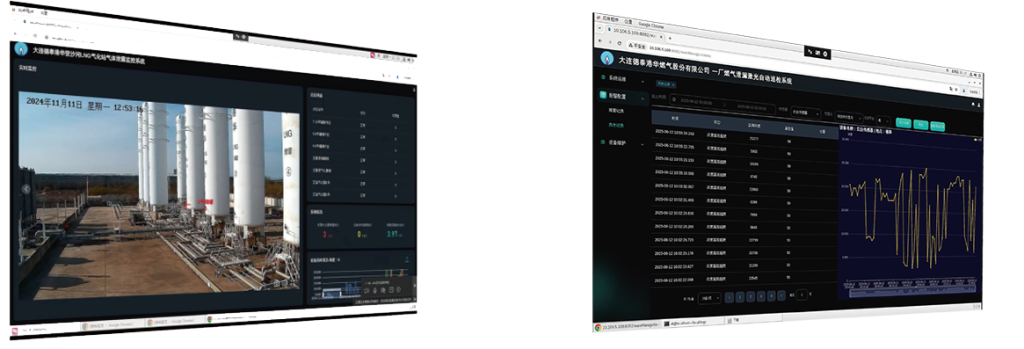

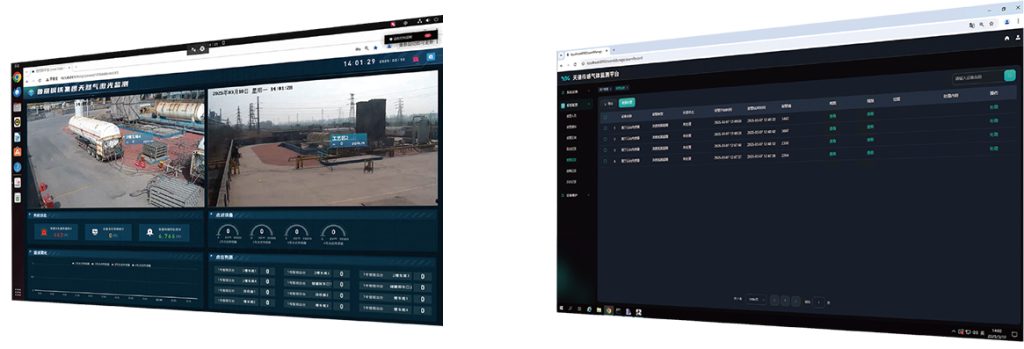

Digitized platform

On site concentration and video monitoring

Alarm configuration and recording

On site concentration and video monitoring

Alarm configuration and recording